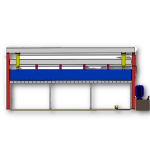

✅ High-Rigidity Machine Structure: Constructed with heavy-duty cast iron to withstand high-speed machining forces.

✅ Advanced Cooling System: Utilizes a closed-loop coolant circulation system to maintain stable spindle temperatures.

✅ Automatic Tool Length Measurement: Equipped with a non-contact measuring device for quick and accurate tool setting.

✅ High-Speed Data Transmission: Features a fiber-optic communication system for seamless control and data transfer.

✅ Competitive Advantages:

Integrated Error Correction: Real - time error compensation algorithms to ensure consistent quality.

Quick - Change Tooling System: Reduces tool change time by 40%, increasing productivity.

Remote Monitoring and Control: Allows for remote operation and troubleshooting via a secure cloud - based platform.

Affordable Pricing:Cutting out middlemen, it directly benefits customers, reducing procurement costs by 10%-20% compared to middleman-sourced purchases.

Affordable Pricing:Cutting out middlemen, it directly benefits customers, reducing procurement costs by 10%-20% compared to middleman-sourced purchases. Overpriced:Marked up by middlemen, increasing procurement costs.

Overpriced:Marked up by middlemen, increasing procurement costs.