✅ Heavy-duty steel frame with 2000MPa compressive strength

✅ Optional CNC control system (±0.1mm accuracy)

✅ Hydraulic drive for processing up to 50mm thick plates

✅ Safety interlock & emergency braking system

| Function | Specification |

|---|---|

| Material | Stainless Steel/Carbon Steel/Aluminum/Copper |

| Max Thickness | 50mm (2 Inches) |

| Min Bend Radius | 1.5×Material Thickness |

| Drive System | Hydraulic Power (50kW Motor) |

| Control Mode | Manual/Semi-Auto/CNC (Optional) |

| Parameter | Value |

|---|---|

| Roller Diameter | 320mm |

| Roller Length | 2500mm |

| Working Pressure | 20-30MPa |

| Machine Weight | 12,000kg |

| Power Supply | 380V/50Hz/3 Phase |

Consult&Select

Quotation&Negotiation

Order&Sign

Produce&Inspection

Packing&Shipping

Final payment

Delivery&Check

After-sale

Processing Materials:

Type:Tell the manufacturer if the material is metal (e.g., carbon steel, stainless steel, aluminum alloy) or non-metal (e.g., plastic, wood). Material properties affect cutter and power selection.

Dimensions:Provide thickness, length, width of sheets or diameter, length of bars. This decides if the worktable size and processing stroke fit. For a 50mm-thick, 1000mm-wide, 3000mm-long steel plate, the machine must handle it.

Accuracy:

Dimensional:Detail the part's dimensional tolerance. For a shaft with ±0.01mm diameter tolerance, the machine needs the right accuracy.

Form:Inform form accuracy like roundness, straightness, flatness. A 0.05mm - flat disc requires proper machine motion and tech.

Production:

Batch:State if it's single-piece, small-batch (dozens per time) or large-batch (hundreds+per time). It impacts the automation and efficiency of the recommended machine. Large-batch needs high-automation, fast-processing tools.

Cycle:Set the expected time per workpiece. If one part in 5 minutes, the machine's cutting speed, tool-change time must meet the mark.

Special Needs:

Automation:If you want auto-load/unload or auto-tool-change, let the manufacturer know for proper configuration.

Environment:Share workplace space, temperature, humidity. Some machines have specific needs, and space affects installation. Limited space may need a compact model.

Installation and Commissioning:

Send professionals to help customers install the machine tool following correct procedures.

After installation, conduct full-scale commissioning to optimize performance.

Training:

Provide operators training on operation, maintenance, and troubleshooting.

Offer customized training for different customer levels.

Fault Repair:

Set up a rapid-response mechanism. First, diagnose problems remotely and provide solutions.

If needed, send experienced repairmen with tools and spare parts to fix on-site quickly.

Spare Parts Supply:

Ensure sufficient inventory and monitor stock in a sound management system.

Provide worldwide delivery with reliable logistics and tracking info.

Quality Assurance:

During the warranty period, offer free repairs or replacements for quality-related issues.

Regularly visit customers to collect feedback and improve products.

Technical Upgrades:

Keep up with technology to offer upgrades, like enhancing control systems or software.

Provide relevant info and advice, and customize upgrade plans.

I. Shipper Information:

Shipper: [Shipper's Company Name]

Address: [Shipper's Company Address]

Contact Number: [Shipper's Contact Number]

II. Consignee Information:

Consignee: [Consignee's Company Name]

Address: [Consignee's Company Address]

Contact Number: [Consignee's Contact Number]

III. Shipment Information:

Port of Loading: [Specific Port Name]

Port of Destination: [Specific Port Name]

Estimated Shipping Date: [Specific Date]

Estimated Arrival Date: [Specific Date]

IV. Goods Details:

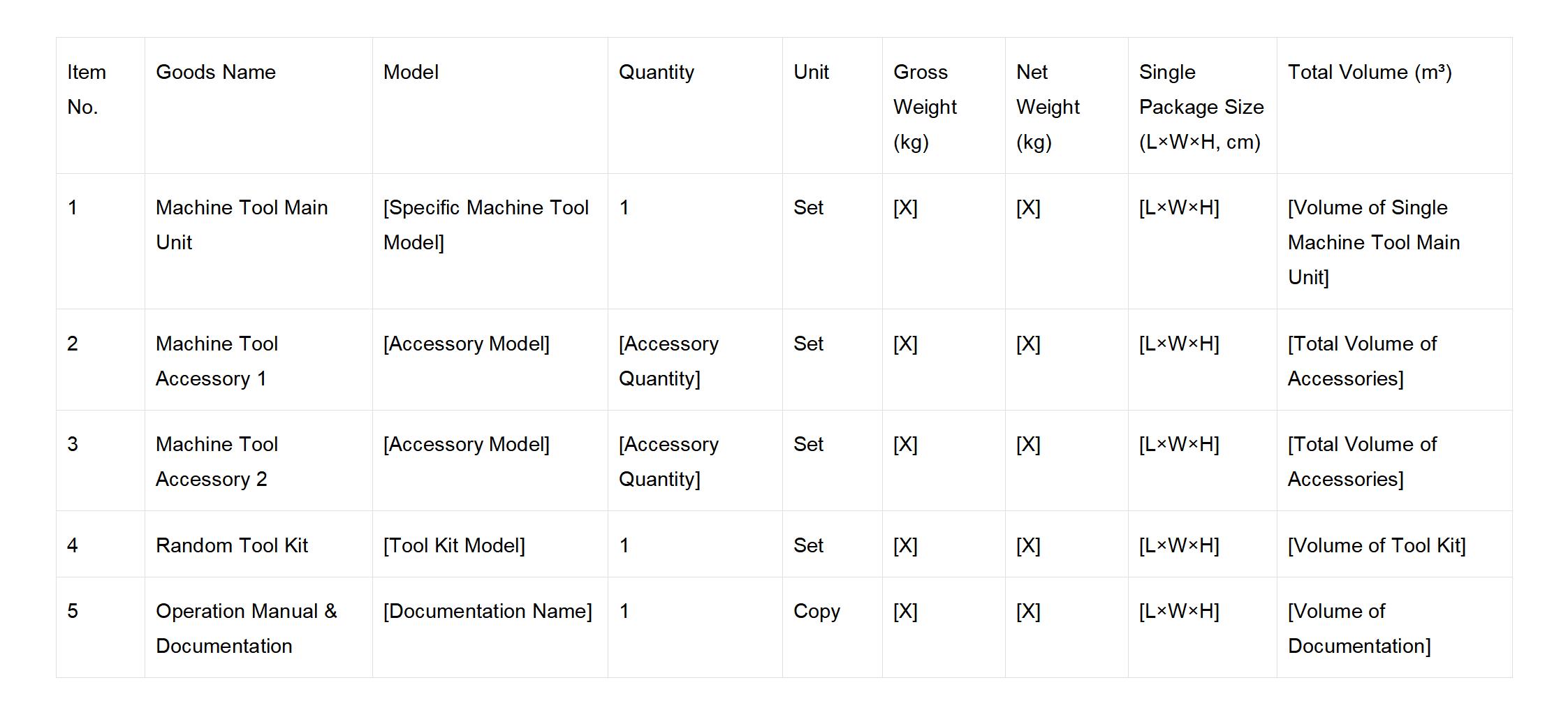

Refer to the right-hand figure

V. Packaging Information:

1.Machine Tool Main Unit: Packed in a wooden box with steel straps reinforced outside to ensure safety during transportation.

2.Machine Tool Accessories: Packed separately in cartons filled with cushioning materials like foam to prevent collision damage.

3.Random Tool Kit: Placed in a dedicated tool kit box with fixed compartments to keep tools from shaking.

4.Operation Manual & Documentation: Put into a waterproof document bag and then placed in a carton.

VI. Remarks:

1.The information filled in this list is consistent with the actual goods. In case of any differences, the actual goods shall prevail.

6.The goods have been packaged in accordance with relevant standards to ensure no damage during transportation. However, the consignee is requested to carefully check the integrity of the goods packaging upon receipt. If there are any abnormalities, please contact the shipper in a timely manner.

JQMT Inc. focuses on providing customers with comprehensive and high-quality machine

tool services.Our engineer team can offer professional consultation, accurately

recommending suitable machine tool models according to your needs.

When choosing a machine tool manufacturer, focus on product quality,

with high precision and stability being crucial. The manufacturer

should have strong production capabilities to ensure delivery and meet customized needs.

Their technical strength must be solid, with innovative achievements.

After-sales service should feature quick response and effective maintenance.

Regarding price, emphasize cost-effectiveness and transparency.

Also, refer to industry reputation and successful cases, and check for relevant qualification certifications.

Make a choice after comprehensive consideration.

| Items | JQMT INC. | Others |

|---|---|---|

| Price |  Affordable Pricing:Cutting out middlemen, it directly benefits customers, reducing procurement costs by 10%-20% compared to middleman-sourced purchases. Affordable Pricing:Cutting out middlemen, it directly benefits customers, reducing procurement costs by 10%-20% compared to middleman-sourced purchases. |

Overpriced:Marked up by middlemen, increasing procurement costs. Overpriced:Marked up by middlemen, increasing procurement costs. |

| Quality |  Quality Control:Overseeing the entire production process, from raw materials to final assembly, ensures stable product quality. Quality Control:Overseeing the entire production process, from raw materials to final assembly, ensures stable product quality. |

Quality Uncertainty:Not the direct producer, with insufficient quality control and a tendency to shirk responsibility when issues arise. Quality Uncertainty:Not the direct producer, with insufficient quality control and a tendency to shirk responsibility when issues arise. |

| After-sales |  Prompt After-sales:With an in-house after-sales team, it can respond rapidly, resolve equipment failures quickly, and minimize downtime. Prompt After-sales:With an in-house after-sales team, it can respond rapidly, resolve equipment failures quickly, and minimize downtime. |

Delayed After-sales:Requires coordinating with manufacturers, resulting in slow information transfer and untimely repairs. Delayed After-sales:Requires coordinating with manufacturers, resulting in slow information transfer and untimely repairs. |

| Customization |  Flexible Customization:Deep understanding of production processes allows for customized machine tools based on customer needs. Flexible Customization:Deep understanding of production processes allows for customized machine tools based on customer needs. |

Limited Customization:Limited understanding of production processes makes it difficult to meet special customer needs. Limited Customization:Limited understanding of production processes makes it difficult to meet special customer needs. |

| Support |  Professional Technical Support:Factory technicians offer professional operation training and technical guidance. Professional Technical Support:Factory technicians offer professional operation training and technical guidance. |

Inadequate Technical Guidance:Lacking a professional technical team, unable to provide comprehensive training. Inadequate Technical Guidance:Lacking a professional technical team, unable to provide comprehensive training. |

| Reputation |  Reliable Reputation:Backed by factory strength, it has built a good reputation in the industry. Reliable Reputation:Backed by factory strength, it has built a good reputation in the industry. |

Unclear Reputation:Some companies have poor reputations, with potential fraud or concealment issues. Unclear Reputation:Some companies have poor reputations, with potential fraud or concealment issues. |

| Upgrades |  Fast Product Upgrades:Direct exposure to market demands enables timely improvements and new product launches. Fast Product Upgrades:Direct exposure to market demands enables timely improvements and new product launches. |

Slow Product Updates:Multiple information transfer links make it hard to keep up with market demands in a timely manner. Slow Product Updates:Multiple information transfer links make it hard to keep up with market demands in a timely manner. |

| Spare Parts |  Stable Spare Parts Supply:The in - house production system ensures timely spare parts supply, reducing maintenance costs. Stable Spare Parts Supply:The in - house production system ensures timely spare parts supply, reducing maintenance costs. |

Unstable Spare Parts Supply:Relying on external suppliers leads to long maintenance cycles and high costs. Unstable Spare Parts Supply:Relying on external suppliers leads to long maintenance cycles and high costs. |

| Production |  Transparent Production:Customers can visit the factory to understand the production process, enhancing trust. Transparent Production:Customers can visit the factory to understand the production process, enhancing trust. |

Opaque Production:Customers find it difficult to understand the production process, with trust risks. Opaque Production:Customers find it difficult to understand the production process, with trust risks. |

| Cooperation |  Long-term Cooperation Assurance:Focusing on long-term development, it provides continuous services and support to customers. Long-term Cooperation Assurance:Focusing on long-term development, it provides continuous services and support to customers. |

Short-term Focused Cooperation:Some companies prioritize short-term benefits and neglect long-term services. Short-term Focused Cooperation:Some companies prioritize short-term benefits and neglect long-term services. |

Thanks to customers for trust and support!

Stable supply of hot selling products, timely delivery, and affordable prices

Embrace our products, set sail with precision and efficiency!